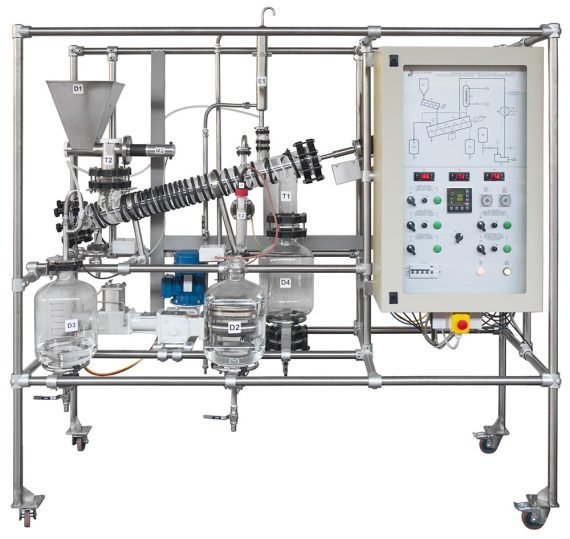

Flow and pressure control system Mod. REGA-F/EV – is a modern educational equipment for studying the flow and pressure control of liquids (water) and gases (air). This system includes four types of flow meters and a closed circuit with a tank and a recycling pump. SCADA software allows for monitoring and control of the system via a computer.

Technical characteristics:

- Construction:

- Frame made of AISI 304 stainless steel with wheels;

- AISI 304 stainless steel 80 l tank;

- Centrifugal pump (Q = 4 m³/h, pressure – 30 m) with stainless steel housing and rotor.

- Measuring devices:

- Venturi tube made of transparent Plexiglas®;

- Calibrated diaphragm made of AISI 304 stainless steel;

- Electronic magnetic induction flow transmitter (AISI 316) with 4-20 mA output signal;

- Electronic variable range flow transmitter-indicator (AISI 316), range 40–4000 l/h, 4–20 mA output signal.

- Control devices:

- 2 pneumatic pressure control valves (AISI 316) for split-range control;

- Pneumatic flow control valve (AISI 316, Cv = 5);

- 3 electro-pneumatic transducers (4–20 mA / 0.2–1 bar);

- Electronic microprocessor PID controller with LCD display and serial interface.

- Security and monitoring:

- IP55 panel with emergency stop button;

- SCADA software (Windows) for control and data acquisition functions, real-time and historical data analysis.

Educational program:

- Proportional, Integral, and Derivative Control (PID) analysis;

- Operation of pressure and flow measuring devices;

- Analysis of process reactions and characteristics;

- Controller tuning techniques;

- Liquid and gas flow and pressure control;

- Split-range control techniques;

- System monitoring via SCADA.

General data:

- Power supply: 230 Vac, 50 Hz, single-phase, 1.5 kVA;

- Dimensions: 2200 × 750 × 2000 mm;

- Weight: 250 kg.

Resources needed:

- Compressed air: 1 Nm³/h at 6 bar for instruments, 50 Nm³/h at 6 bar when the process fluid is air;

- Water supply: tap with ½” connection.