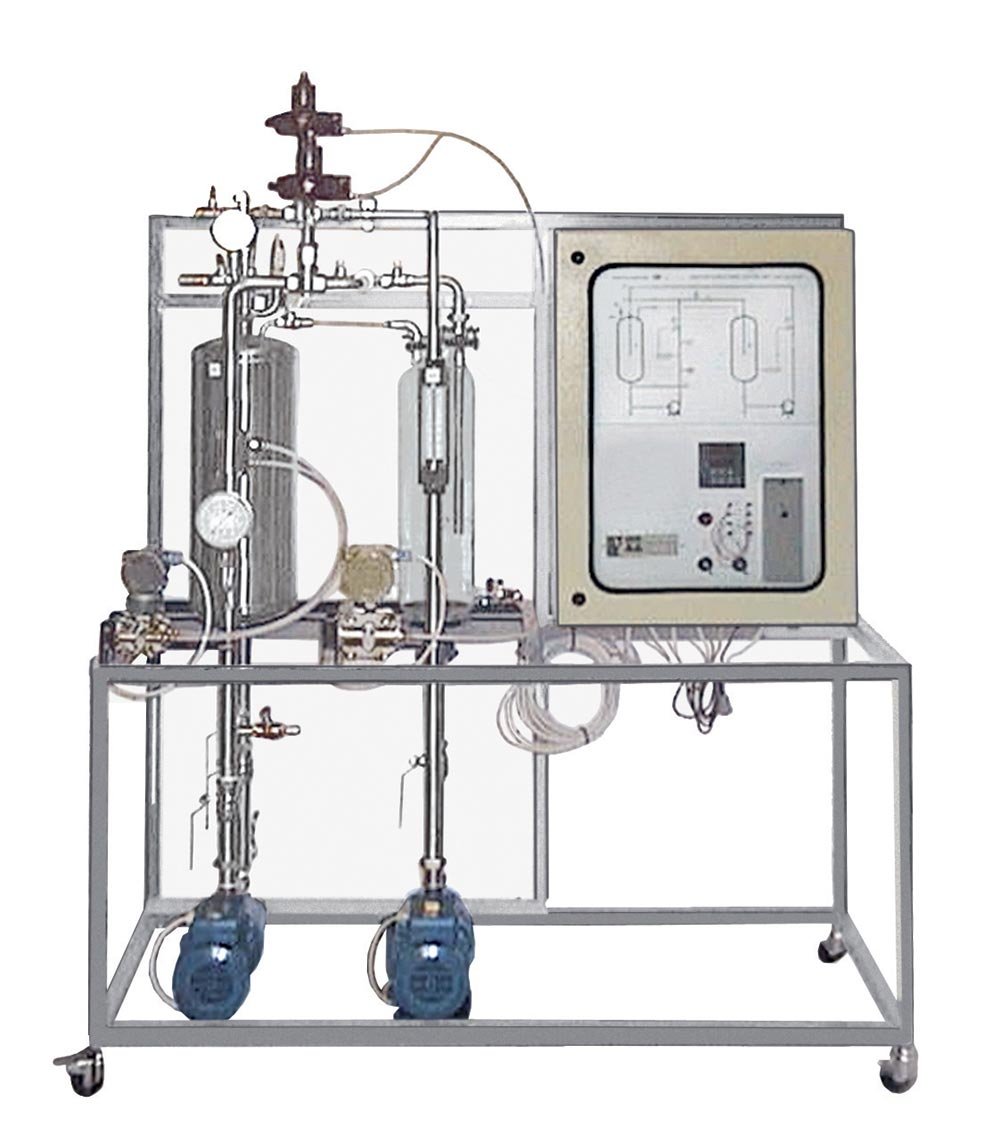

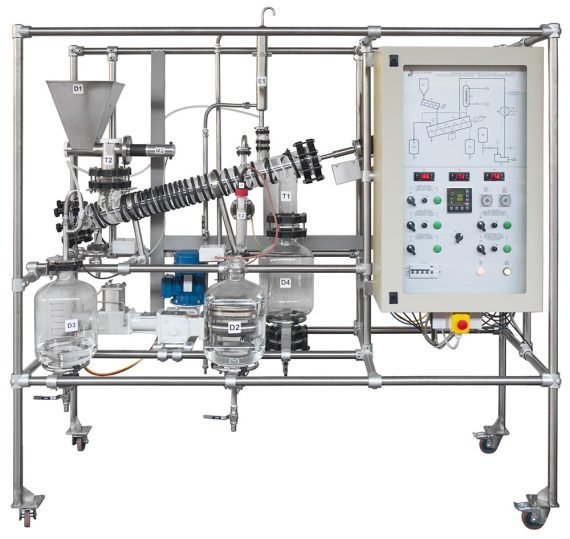

Flow and level control stand Mod. FLC/EV is a training system designed to teach the principles of industrial process control. The stand uses a borosilicate glass column fed by a central pump connected to a water tank. A recirculation pump returns water from the column back to the reaction vessel. The flow rate and column level can be precisely adjusted using pneumatic valves, and a SCADA software package for control and data acquisition allows the system to be monitored and controlled via a computer.

Technical characteristics:

- Construction: AISI 304 stainless steel frame with wheels;

- Container: Water storage tank (AISI 304 stainless steel) – 20 l capacity;

- Column: Borosilicate glass, DN 100, height 600 mm;

- Pumps:

- Two centrifugal recirculation pumps with AISI 304 steel housing and rotors, Q = 4 m³/h;

- Measuring equipment:

- Electronic differential pressure sensor (AISI 316 stainless steel) for flow measurement, with 4-20 mA output signal;

- Electronic differential pressure sensor (AISI 316 stainless steel) for level measurement, range: 0–500 mm H₂O, with 4–20 mA output signal;

- Valves:

- Two AISI 316 stainless steel pneumatic control valves, Cv = 2.5;

- Controls:

- Electronic microprocessor PID controller with serial port;

- Two electro-pneumatic transducers (4–20 mA / 0.2–1 bar);

- Other components:

- Calibrated diaphragm (AISI 304 steel);

- Safety valve;

- IP55 switchboard with EC conformity mark, including plant synoptics and fuses.

SCADA software:

- Controls on/off signals, analog signals from the PID controller;

- Real-time and historical data tracking and analysis.

Technical data:

- Power supply: 230 Vac, 50 Hz, single-phase, 2 kVA (other voltages and frequencies available on request);

- Dimensions: 1500 × 700 × 1900 mm;

- Weight: 140 kg.

Educational program:

- Proportional, integral and derivative (PID) control analysis;

- Use of flow and level measuring devices;

- Study of process response and characteristics;

- Control regulation methodologies;

- System maintenance using SCADA software.