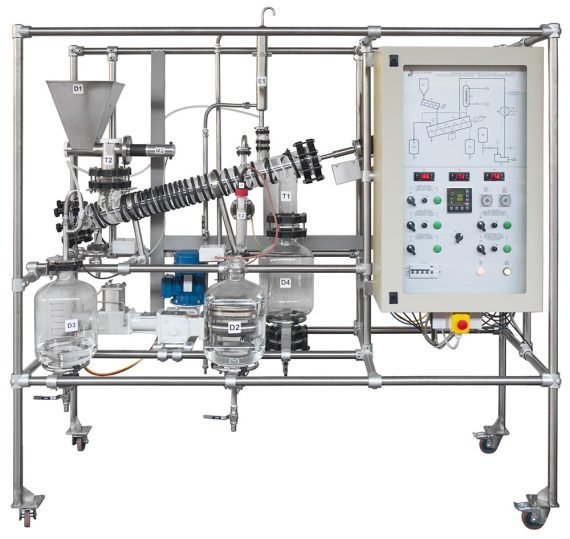

Pressure and flow control system Mod. REGA-P/EV is a modern educational equipment for analyzing and understanding pressure and flow control processes. The device includes a hydraulic circuit that allows you to regulate the pressure and flow of compressed air or water. The system is designed to study the dependence of control parameters on the volume of the system, using three tanks and pneumatic valves. Using SCADA software, you can monitor and control the system from a computer.

Technical characteristics:

- Construction:

- AISI 304 stainless steel frame with wheels;

- 3 AISI 304 stainless steel tanks (DN 200, capacity – 20 l);

- Control valves:

- 2 pneumatic valves (AISI 316, Cv = 2.5) for pressure and flow control;

- 1 pneumatic valve (AISI 316, Cv = 0.32) for flow control;

- Measuring equipment:

- Electronic pressure transmitter (AISI 316, range 0–6 bar, 4–20 mA output);

- Differential pressure transmitter (AISI 316, for flow measurement, 4-20 mA output);

- Control equipment:

- Electronic PID controller with four-line LCD display and serial communication card;

- 3 electropneumatic transducers (4–20 mA / 0.2–1 bar);

- Pipelines and valves: AISI 304 and 316 stainless steel;

- Electrical panel: IP55 class, compliant with EC requirements, with synoptic diagram and fuse (ELCB);

- Protective measures: Emergency stop button;

- SCADA software:

- Allows monitoring and control of ON-OFF and analog signals from the PID controller;

- Real-time and historical data analysis.

Technical data:

- Power supply: 230 Vac, 50 Hz, single-phase, 1 kVA (other voltages and frequencies available upon request);

- Dimensions: 1900 × 750 × 1900 mm;

- Weight: 220 kg.

Educational program:

- Analysis of PID control methods;

- Split-range control;

- Principles of operation of pressure and flow measuring devices;

- Study of process characteristics;

- Controller tuning techniques;

- System monitoring via SCADA program.