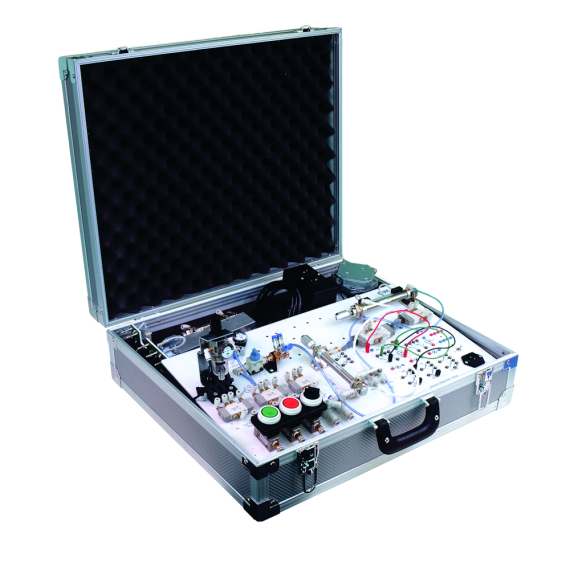

SMC España SAU MAS-200 modular assembly simulator

- MAS-200

- Modular training systems that simulate the real industrial assembly process.

- Consisting of five stations, each performing part of the assembly of the final product.

- The stations are completely autonomous, allowing them to form a complete production cell.

- MAS-200 components are used in industry, providing detailed knowledge of automated industrial technologies.

- Including a SCADA tool that allows you to monitor the status of devices, control the process in real time, and generate statistics.

- MAS-201: Base feeding with incorrect parts detection and ejection

- The base is fed, checking the orientation and moving it to the mounting position.

- Including the TROUB-200 fault simulation system.

- MAS-202: Lid positioning

- Inserts the cover into the work piece.

- Including the TROUB-200 fault simulation system.

- MAS-203: Bearing Insertion

- Feed the bearing and move it to the installation position.

- Including the TROUB-200 fault simulation system.

- MAS-204: Shaft Insertion

- Feed the shaft and move it to the installation position.

- Including the TROUB-200 fault simulation system.

- MAS-205: Parts transfer

- Responsible for assembling or dismantling all parts received from other stations.

- There are two versions: with a pneumatic index plane or with a six-axis robot.

- The PLC in this station is the network master for the PLCs in the other stations. It contains a control panel, keyboard, alarm, power supply, and connections for air and electricity.

- MAS-205B: Robotic transfer

- The opportunity to study robotics is included, performing tasks of assembling and disassembling all parts.

- The robot performs assembly and disassembly tasks with two rotating tools.

- Including the TROUB-200 fault simulation system.

Automation – Simulators – SMC

More information: on the manufacturer's website or send us an inquiry!