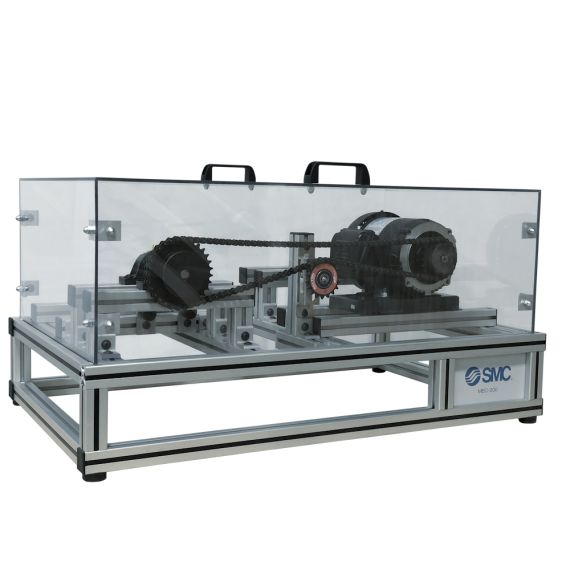

SMC España SAU ENS-200 Energy Saving Simulator

- ENS-200 – integrates vacuum, actuators and blowing applications to understand and implement methodology related to energy savings in compressed air installations.

- It will teach you how to detect potential excess consumption and suggest actions to avoid it.

- Analyze different scenarios through guided sessions, where each experiment shows how much you saved, both as a percentage and in your chosen currency.

- It operates on four basic principles of energy saving in pneumatics:

- PRESS – pneumatic components must be set accurately with a legal press, as consumption is proportional to the working pressure.

- SECTORIZATION – this means division. It is possible to sectorize, designed for different zone working pressures. It is also possible to sectorize by area, minimizing the impact of leaks in the inactive zone.

- OBSERVATION – this means measuring to identify equipment defects and estimate the savings that can be made by repairing them. Monitoring can be done continuously or occasionally, and it also leads to prevention, i.e. knowing when a part of the equipment starts using more energy due to leaks or other faults.

- AIR QUALITY – A dirty filter causes a drop in pressure. If this filter is not replaced, the pressure must be increased to continue to meet the system requirements. Poor adherence to this principle has a negative impact on consumption, which leads to the generation of more compressed air.

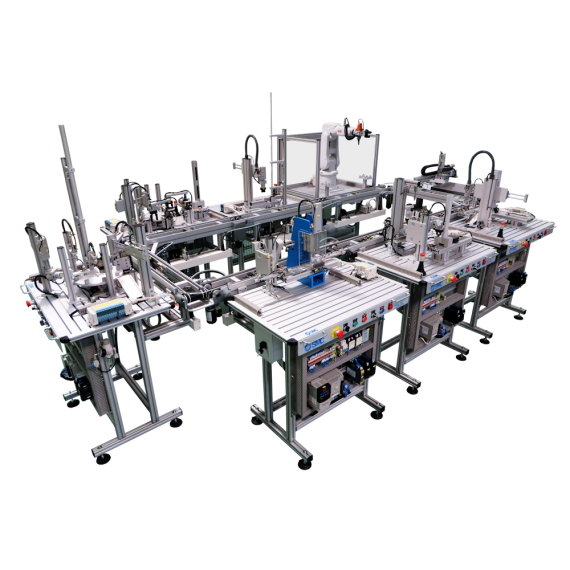

- Main areas: The ENS-200 covers the most common energy sources in an automated process.

Automation – Automation – Simulators – SMC

More information: on the manufacturer's website or send us an inquiry!