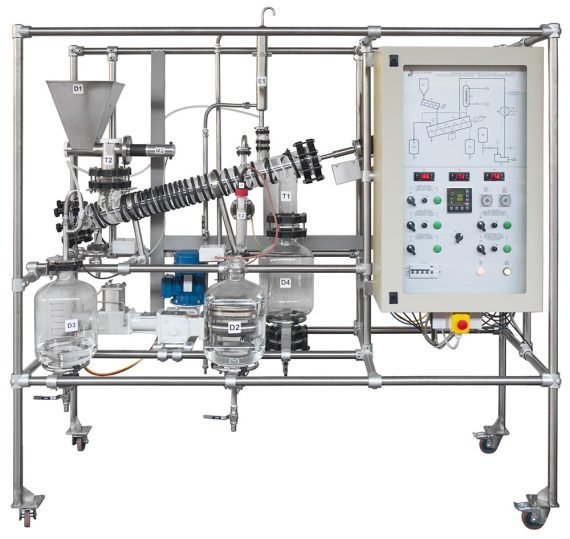

Heat Transfer Test Facility with Plate and U-Shaped Heat Exchanger UTC-1/EV

Full description:

This test rig is designed for heat exchange studies using U-shaped and flat plate heat exchangers. The automated version (mod. UTC-1a/EV) includes a PID controller that automatically regulates the flow rate through two pneumatic valves.

Training program allows you to explore the following topics in more detail:

- Heat transfer between fluids separated by a wall

- Energy balance and efficiency calculation

- Logarithmic mean temperature difference (LMTD) determination

- Overall heat transfer coefficient (U)

- How flow rate and temperature difference can affect the transfer coefficient

- Comparison of operating modes and efficiency of different types of heat exchangers

- Automatic flow control with PID controller (only mod. UTC-1a/EV)

- System maintenance via computer (only mod. UTC-1a/EV)

Technical specifications:

Mod. UTC-1/EV

- Frame made of AISI 304 stainless steel with casters

- U-shaped heat exchanger with AISI 304 stainless steel tubes and borosilicate glass body, heat transfer surface – 0.6 m²

- Plate heat exchanger made of AISI 316 stainless steel, heat transfer surface – 0.6 m²

- 2 variable area digital flow meters, glass and steel, flow range 100–1000 l/h (only mod. UTC-1/EV)

- 4 Pt 100 temperature sensors with AISI 316 stainless steel housing

- 4 electronic temperature indicators

- Pipelines and valves made of AISI 304 and AISI 316 stainless steel

- IP55 control panel, compliant with EC marking requirements, with installation diagram and ELCB

- Emergency button

Mod. UTC-1c/EV

- In addition to all the features of the UTC-1/EV model, this model also has:

- 2 electronic magnetic induction flow meters made of AISI 316 stainless steel, flow range 0–1000 l/h, 4–20 mA output signal

- PC interface built into the control panel

- Data acquisition software for Windows operating system

Mod. UTC-1a/EV

- In addition to all the features of the UTC-1/EV model, this model also has:

- 2 electronic magnetic induction flow meters made of AISI 316 stainless steel, flow range 0–1000 l/h, 4–20 mA output signal

- 2 pneumatic valves in AISI 316 stainless steel (Cv = 2.5) for flow control

- Microchip digital PID controller with serial card

- System maintenance software for Windows: it allows you to control ON-OFF signals, analog signals from the PID controller, real-time and historical trends

Power supply: 230 Vac 50 Hz single phase – 0.5 kVA (other voltage and frequency on request)

Dimensions: 1500 × 700 × 1800mm

Weight: 130 kg