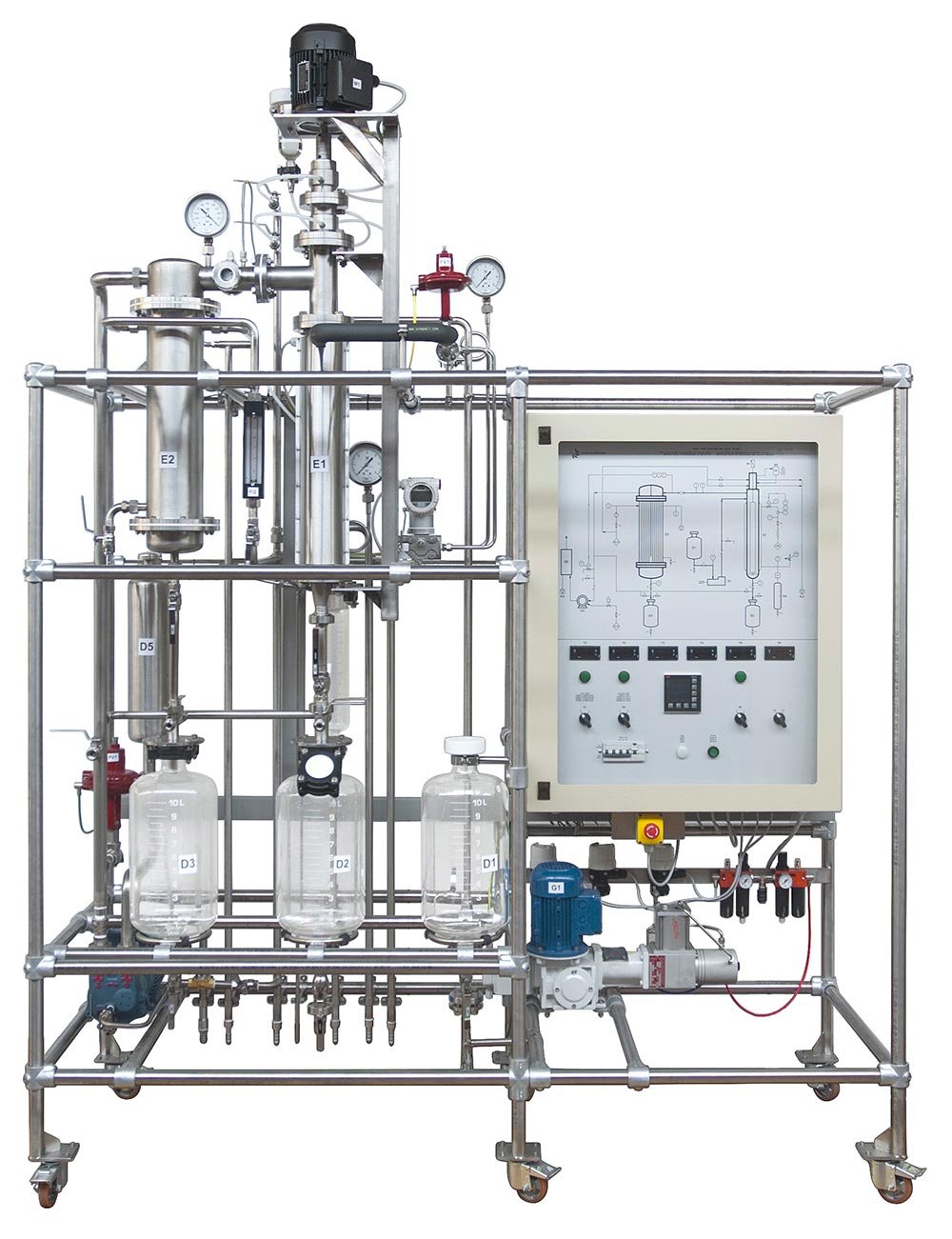

Thin Film Evaporation Test Station THIN FILM EVAPORATION PILOT PLANT – is a training system for the concentration of solutions, especially suitable for heat-sensitive, viscous or easily contaminated products, such as sugar, vitamin, protein solutions, fruit juices or fermentation broths. The evaporation process takes place in a cylindrical container, which is equipped with a steam heating jacket and a three-blade rotor, forming an extremely thin liquid layer on the walls.

Automated version (ESSa/EV) allows automatic control of steam flow and system vacuum via PID controller and monitoring of the process by computer.

Curriculum:

This station provides an opportunity to examine the following processes in detail:

- Mass and energy balances;

- Determination of the overall heat transfer coefficient;

- Optimization of the evaporation process;

- Automatic flow and vacuum control (only EU/EEA model);

- System monitoring and control via computer (only EU/EEA model).

Technical specifications (ESS/EV):

- AISI 304 stainless steel frame with wheels;

- Borosilicate glass containers:

- For feed (10 l),

- For concentrated solution (10 l),

- For evaporated solvent (10 l);

- AISI 316 stainless steel film evaporator with:

- Three-blade rotator (0–1500 rpm),

- Heat exchange surface 0.12 m²,

- Evaporation capacity up to 10 kg/h H₂O;

- AISI 304 stainless steel piping, valves and heat exchanger (1.1 m²);

- Pneumatic dosing pump with adjustable flow (0–20 l/h);

- Liquid ring vacuum pump with air/water separator;

- PID controller and pneumatic valves for steam flow and vacuum control (ESSa/EV);

- 6 Pt100 temperature sensors and electronic indicators;

- Differential pressure and vacuum transmitters with 4–20 mA signal output (ESSc/EV and ESSa/EV);

- IP55 switch with CE marking, emergency button and ELCB protection.

Dimensions and weight:

- Dimensions: 2100 × 800 × 3000 mm;

- Weight: 260 kg.