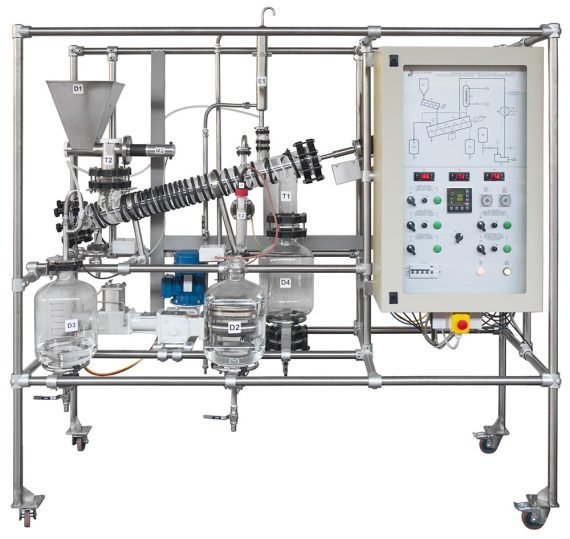

Continuous Reaction (CSTR) Test Equipment REC1/EV designed to study the kinetics of a continuous reaction by changing the electrical conductivity readings in the reactor. This reactor is equipped with an electric heater and a distillation column with a condenser. Automated version Mod. REC1a/EV has a PID controller that automatically controls the reaction temperature. The equipment allows you to delve into reaction kinetics, thermodynamics, mass and energy balance. Possible tasks include the kinetics of ethyl acetate hydrolysis and the transformation of acetic anhydride to acetic acid, showing the reaction kinetics by measuring conductivity.

Technical specifications:

- AISI 304 stainless steel frame with casters

- Two 10 liter AISI 316 stainless steel feeding tanks

- 20 liter AISI 316 stainless steel product collection tank

- Two AISI 316 stainless steel dosing pumps (flow rate 0-8.4 l/h)

- 3 liter borosilicate glass reactor with 1.0 kW electric heater

- Reactor agitator with mechanical seal, lubricated with silicone oil, 0–400 rpm.

- Distillation column made of borosilicate glass, DN25

- AISI 304 stainless steel condenser

- Borosilicate reagent vessels (1 l capacity) and collection vessels (2 l capacity)

- 2 Pt 100 temperature sensors, AISI 316 stainless steel housing

- Electronic conductivity meter with automatic temperature compensation

- Vacuum connection system with non-return valve system

- Vacuum gauge AISI 304 stainless steel, with a range from 0 to -1 bar

- Piping and valves made from AISI 304 and AISI 316 stainless steel

- IP55 protection degree control panel with EC mark