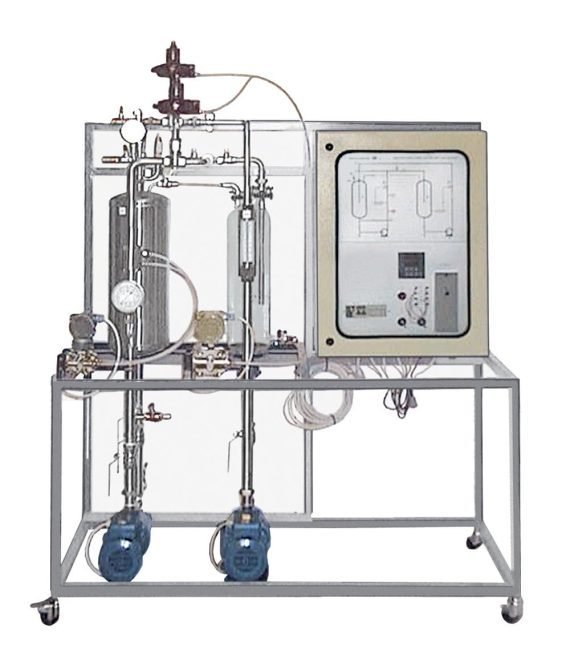

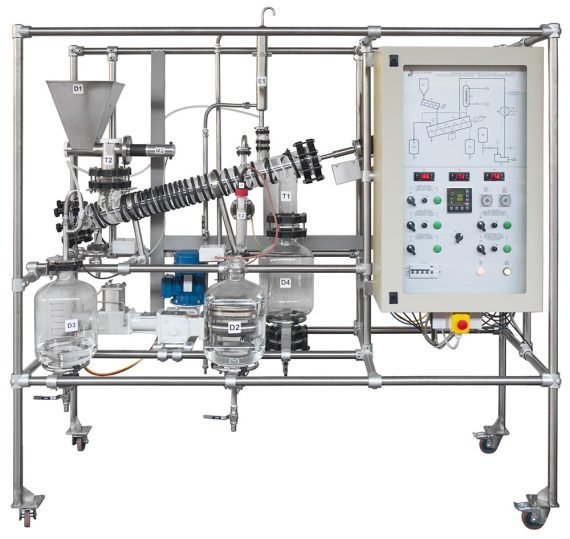

Coagulation, flocculation and sedimentation test station FSE/EV – an advanced system for modeling and optimizing water treatment processes. This equipment allows you to study coagulation, flocculation and sedimentation processes separately or together, using precise technological tools. Mod. FSEa/EV version has automatic PID control and remote monitoring of parameters via specialized software.

Curriculum:

This system allows you to analyze the following aspects:

- Coagulation process;

- Flocculation process;

- Parallel and counter-parallel deposition;

- Properties of coagulants and flocculants;

- Optimization of coagulation, flocculation and sedimentation processes;

- Automatic PID control (only Mod. FSEa/EV);

- Remote system maintenance (only Mod. FSEa/EV).

Technical characteristics:

- AISI 304 stainless steel construction with casters;

- Transparent cylindrical feed tank (300 l) with submersible pump;

- Transparent coagulant container (60 l);

- Glass flocculant container (0.5 l) with heating plate and magnetic stirrer;

- Coagulation reactor made of borosilicate glass (30 l), with motor-driven stirrer (0–300 rpm);

- Flocculation reactor made of borosilicate glass (8 l), with motor-driven mixer (0–100 rpm);

- Rectangular sedimentation tank made of transparent methacrylate with conical bottom and movable plates for parallel and counter-sedimentation;

- Feed flow meter (30–300 l/h);

- Coagulant flow meter (2–20 l/h);

- Feed screw pump (AISI 316) with frequency converter, flow rate up to 200 l/h;

- AISI 316 gear coagulant pump, flow rate up to 50 l/h;

- Flocculant dosing pump, flow rate up to 200 ml/h;

- IP55 control panel with CE marking and synoptic control.

Dimensions and power supply:

- Dimensions: 1800 × 800 × 2700 mm;

- Weight: 300 kg;

- Power supply: 230 V, 50 Hz, 1 kVA (other voltage on request).