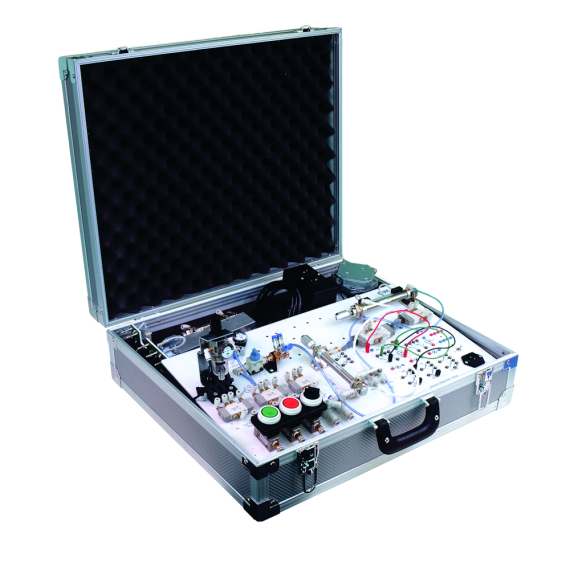

SMC España SAU FMS-200 Flexible Integrated Mounting System

- The modular nature of this flexible automation cell allows for variations in its stations to adapt to the needs of different companies and training centers. From a simple single-station configuration (operating completely autonomously) to a complex configuration with eight or ten stations, the possibilities are endless.

In addition, it facilitates phased investment, i.e. starting with an initial simple configuration that is easy to upgrade by adding workstations.

All components of the FMS-200 are used in industry, so the user can always work with real elements, helping to learn the process.

The system covers a whole range of feeding, conveying, inspection and loading operations, etc., using components from different technologies (pneumatics, hydraulics, sensors, robotics, communications, control and HMI.).

The FMS-200 includes a fault simulation system that generates up to 16 different faults that are diagnosed by the user.

Different process stations have assembled the rotating mechanism. In order to give the system greater flexibility, the stations adapt to different assemblies, introducing variations in materials, colors and part sizes. The combination of all these possibilities allows for up to 24 different assemblies, allowing for the use of production control strategies.

The control panel is fully modular and can be quickly dismantled to allow the user to create and integrate new control. - Each FMS-200 station performs one part of the process:

- FMS-201: Housing supply – This station supplies a base that acts as the foundation for the assembled product.

- FMS-202: Bearing selection/supply – At this station, the bearing is assembled into the base housing.

- FMS-203: Hydraulic press – For this phase, the bearing installed in the previous station is clamped using a hydraulic ram.

- FMS-204: Shaft selection/supply – The shaft is inserted into the product. There are two different shafts made of different materials: aluminum and nylon.

- FMS-205: Lid selection/supply – This station places a lid on the part assembly. There are 6 different lids: depending on material, color and height.

- FMS-206: Screw supply – This station places four screws into the base of the workpiece.

- FMS-207: Robotic competition – Robotics technology is implemented in the seventh FMS-200 station. The robot screws into the four screws inserted into the product at the previous station.

- FMS-208: Automated warehouse – This station stores finished products.

- FMS-209: Dyeing in the dryer – This installation phase simulates the drying process using a polycarbonate dryer.

- FMS-210: Quality control using artificial vision – The addition of this station to the FMS-200 family means the integration of quality control technology through artificial vision. The part is transferred to an inspection position, where an artificial vision camera checks it against a known good part. Size, shape, missing holes – all of this can be checked.

- Transmission system:

- Linear transportation – This is a stationary transport system in which pallets containing work pieces circulate.

- Modular transportation – In this version of the FMS-200, each station includes an individual transfer section. Numerous layout combinations can be created, with the possibility of connecting stations at an angle of 90° or 180° (section in a curved, straight section).

Flexible Integrated Mounting Systems – Simulators – SMC

More information: on the manufacturer's website or send us an inquiry!