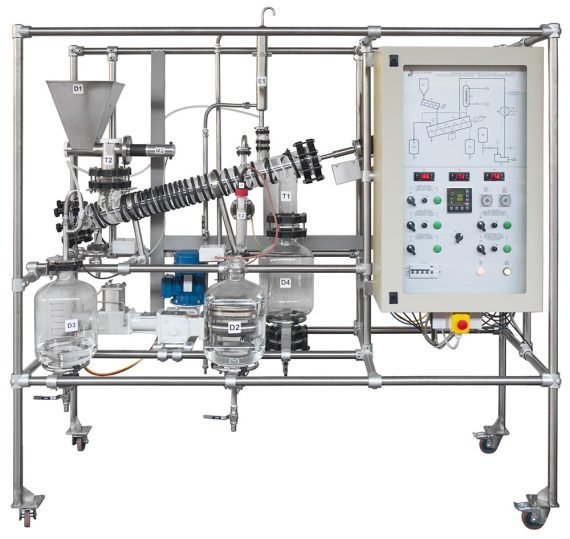

Filter press and microfiltration test station FP-1S/EV – a modern system for the study of different filtration processes. This station allows for the modeling and analysis of both direct filtration (filter press) and tangential filtration (microfilter). The equipment is equipped with a PID controller that allows for maintaining a constant flow rate or pressure, and the monitoring software provides remote control via a computer.

Curriculum:

The station provides the opportunity to study the following processes and parameters:

- Direct filtration using a filter press;

- Tangential filtration using a microfilter;

- Filtering characteristic equation;

- Filtration at constant flow or pressure;

- Displaying the device's operating parameters in a schematic plan in real time;

- Automatic flow and pressure control using PID controller;

- System maintenance via computer.

Technical characteristics:

- AISI 304 stainless steel construction with casters;

- 100 l AISI 304 stainless steel feed tank with a mixing system controlled by a submersible pump;

- 100 l AISI 304 stainless steel collection tank for filtered water;

- Screw feed pump with electronic frequency converter;

- Stainless steel magnetic flow meter with 4-20 mA output signal;

- 3 electronic pressure sensors made of stainless steel with 4-20 mA output signal;

- 2 safety pressure switches;

- Filter press made of AISI 304 stainless steel with transparent Plexiglas frames allowing observation of the process;

- Microfilter with AISI 316 stainless steel body;

- Electronic turbidity meter with 4-20 mA output;

- Digital PID controller with microprocessor and serial card;

- IP55-compliant control panel with CE marking and synoptic control;

- AISI 304 and AISI 316 stainless steel pipelines and valves;

- Emergency button;

- Windows maintenance software that allows you to control ON-OFF signals, monitor PID controller analog signals, and analyze real-time and historical data.

Dimensions and power supply:

- Dimensions: 1500 × 670 × 1900 mm;

- Weight: 150 kg;