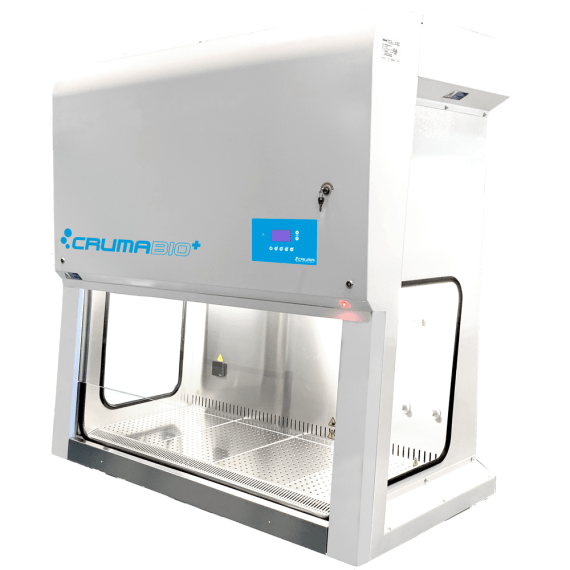

BioAir SpA Safemate ECO+ series microbiological safety cabinet

- Main Features:

- Low energy consumption DC motor fan.

- Latest generation microprocessor control system.

- Large digital display, high resolution.

- Air and aerosol-tight push-button door, electrically operated with the touch of a finger.

- Alarm for low airflow and incorrect front window position.

- Sloped front and back wall for easy access.

- Side windows.

- Front access for filter maintenance and service.

- C-shaped support for a convenient one-person installation process.

- Update rolls are usually installed.

- Safemate ECO+ cabinets are available in four different sizes (0.9, 1.2, 1.5 and 1.8).

These latest generation Microbiological Safety Cabinets Class II Type A2 are certified to the strictest safety standards (EN12469-2000).

The internal design, airflow aerodynamics and monitoring, integrated safety devices and highly precise manufacturing process ensure the highest results, meeting EN12469 standards and certified by the most prestigious European certification bodies for safety cabinets. - Certified biosafety, combined with impressively competitive prices, provides the consumer with an affordable, state-of-the-art cabinet that only experienced European design and precise, high-quality manufacturing process can provide.

The ECO+ series stems from our best-selling series with a more environmentally friendly approach: new DC motor fans feature high efficiency, low energy consumption and air flows are created to reduce noise pollution, ensuring the high level of operator, product and environmental protection required by EN12469-2000 standards. - Main Specifications:

- Microprocessor controlled DC motor blower, with volumetric sensor for exhaust air flow monitoring.

- State of the art Microprocessor control system offering:

- Large screen monitor.

- Automatic control of preset airflow volumes.

- Sliding sash window with smart control.

- Permanent monitoring of HEPA filters life span.

- Alarms. Multilevel alarms, with redundancy functions.

- Permanent display of working conditions.

- Highest air flow stability both in case of transitional disturbances or to progressive filter clogging.

- Continuous monitoring of front barrier air flow for the highest operator safety.

- Low barrier alarm.

- Power failure alarm.

- Volt-free contact for remote monitoring of exhaust fan.

- Automatic reset of initial conditions in case of power failure.

- C-shaped support stand for the easiest one-man installation procedure.

- Mechanical and Functional Specifications:

- 5° Sloped front design increases operating comfort. Sloped rear wall of the working chamber for best downward flow distribution.

- Utility entries from above into the closet.

- Tabletop steel internal surfaces with SB finish (including drain pan). Table or grid structure work surface (30 cm sectors) and specially designed front grill in stainless steel (AISI304 or AISI316).

- Electrically operated sliding laminated safety glass windows.

- Convenient 20 cm front opening.

- Easy to install upgrade options.

- Convenient side windows.

- External exhaust HEPA filter for easy visual integrity inspection.

- H14 class high-performance particulate filter with 99.999% efficiency corresponding to 0.3 micron particles (most penetrating particle diameter) (efficiency >= 99.995% for 0.1-0.2 micron particles MPPS according to EN1822-1).

- ISO 3 (ISO14644-1) internal cleanliness level.

- The suction, intake, and main filters have a micromesh membrane located at the end of the downstream equalizing plenum that acts as an air velocity equalizer expansion chamber and a clear indicator of filter damage.

- Filter replacement and maintenance from the front.

- Exhaust transitions are easy to install.

- Key operation. The key can be removed when the unit is in SAFE mode to prevent unwanted operation. In the event of a power failure, the cabinet is returned to its original condition.

- The self-regulation cycle is performed when the cabinet is turned on.

- A high speed wash and setup cycle is performed before reaching the SAFE operating condition.

- Visual indication of SAFE status. Warning (visual and audible signals) before reaching the actual alarm status.

- Soft touch control keys with keys for standard service tools. Interlinked UV and fluorescent lights.

- Exhaust and recirculation flow rates provide 25 air changes per minute in the work area (30%/70% split).

- Front barrier air velocity ≥ 0.5 m/s.

- Aperture protection factor (Apf) ≥ 1.5 x 10^5.

- Maximum power (for all electrical outlets) 3 Amps.

- Microprocessor equipped with analog watchdog.

- BS version with double exhaust HEPA filter (second filter is inside the main unit, both exhaust filters are tested by DOP test).

- Class I version can be ordered upon request.

- ADDITIONAL FEATURES:

- Active window belt tension control system. This mechanism interrupts the opening of the window, located in the window support belts, when the window is blocked or when an obstacle is detected in its movement. This ensures that the window does not fall suddenly and reduces the risk of crushing during window movement.

- ECO mode: This operating mode allows you to reduce energy consumption and noise levels while ensuring a sterile work area. When activated, the front window will be lowered to a few centimeters from the work surface and the motor will slow down. The smaller opening will allow less air flow to support the front barrier. Operation is not allowed in ECO mode.

- CONTROL PANEL:

- The control keys and LCD display are located on the front of the cabinet.

- The microprocessor will regulate the motor to maintain airflows at set points based on the data returned from the exhaust path cabinet equipped with a built-in wind anemometer.

- Access control is ensured by a key for the user to toggle the ON/OFF switch and a numeric password for accessing the calibration and service menus.

- The following parameters are monitored:

- Laminar vertical flow velocity;

- Barrier air inflow rate;

- Audible/visual signals for insufficient airflow, fan failure, front window position;

- Remaining time of UV rays;

- Hour meters for controllers, HEPA filters, UV lamps.

- Control options:

- Cabinet on/off switch;

- White lights on/off switching;

- Internal sockets on/off switching;

- Gas burner solenoid – OPEN/CLOSE;

- UV lamp timer for setting;

- Activating ECO mode.

- The electronic board provides a voltage-free switch for turning on/off the external fan or for remote control of alarms.

Microbiological Safety Cabinets – BioAir laboratory furniture group

More information: on the manufacturer's website or send us an inquiry!