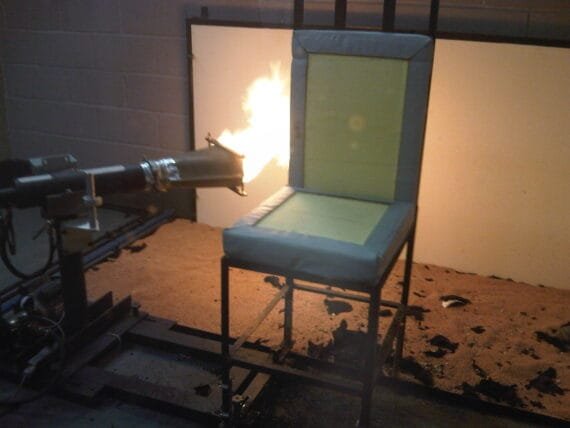

The FAA VFP Vertical Flame Spread Tester is designed to evaluate the flammability of materials located in inaccessible areas of a passenger aircraft. The test uses samples of non-metallic structures, coatings, ductwork, wire insulation, and other components that do not fall within the definition of “small parts” in the FAA flammability regulation.

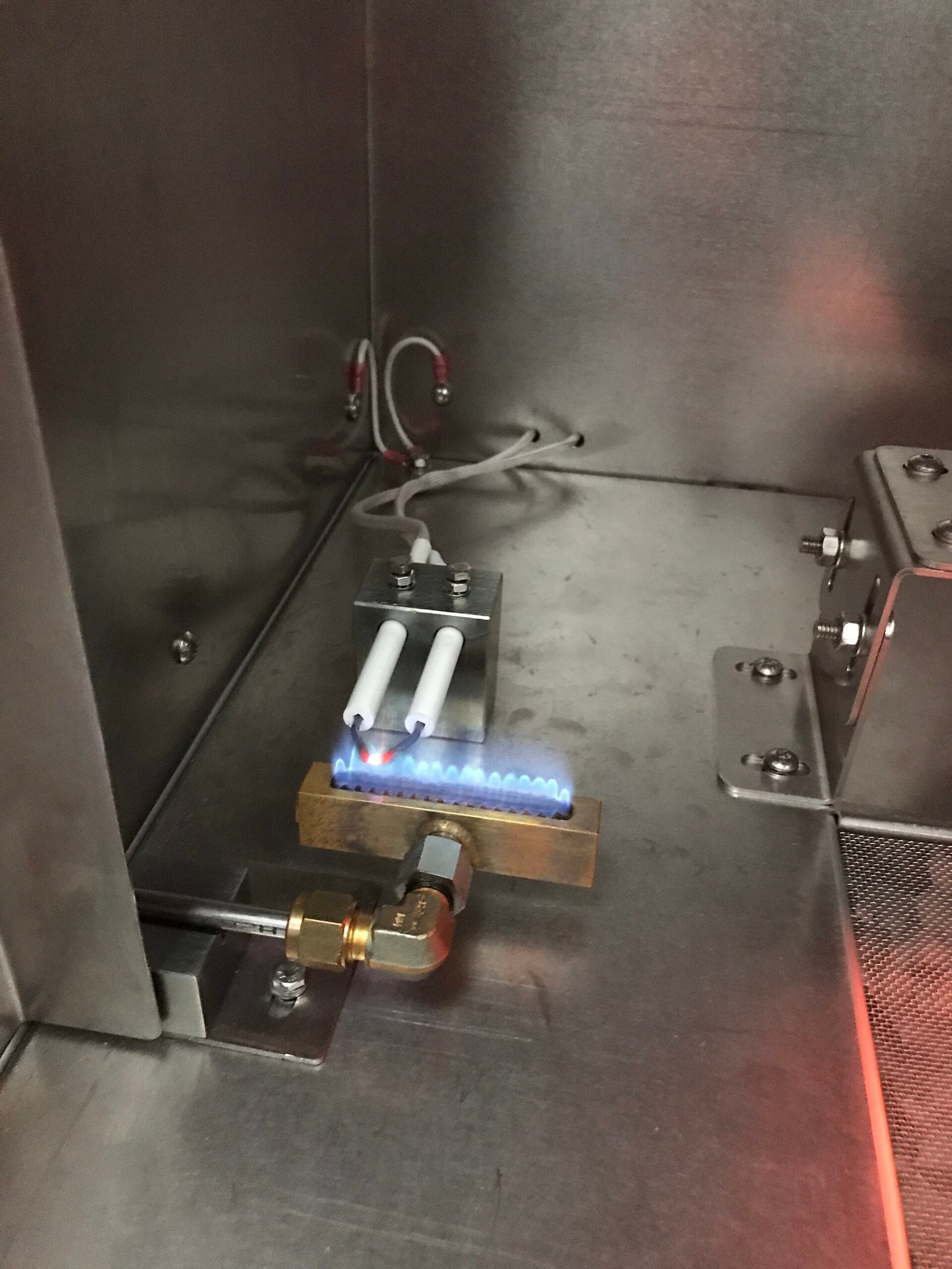

During the test, a 152 mm x 305 mm sample is mounted vertically in front of an electric radiant heating furnace, which provides 1.8 W/cm² of thermal radiation. A special methane/air strip burner creates several intense flames in the lower part of the sample, initiating combustion, and the sample is continuously exposed to radiant heat. After a set time, the burner is automatically removed and the test continues until the material has completely stopped burning. After the test, the length of the burned portion is measured, which is the only criterion for determining whether the sample meets the requirements.

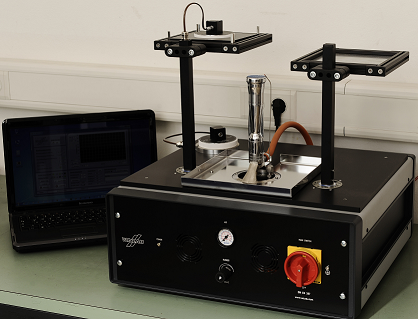

The device ensures a stabilized power supply to the furnace and precise control of methane and air flows to the burner. All main parameters – furnace voltage, ambient temperature, burner operation and flame holding time – are recorded during testing. Additionally, a synchronized video recording function is available.

The FAA VFP test method is included in the new FAA Flammability Test Manual Version 3. The device meets UKCA and CE requirements.

Specifications and features:

- Stainless steel chamber with thermal insulation

- Insulated inner door with sample holder

- Stainless steel chimney and inner roof panel

- Aluminum hexagonal air intake grille with stainless steel guard

- Tempered glass observation windows on the sides and back

- Specially designed radiant heating furnace according to VFP specification

- Automatic burner control with position sensors

- Precise control of electrical power for furnace stabilization

- Gas and air mass flow controllers with computer control

- Automatic test start when the inner door is closed

- Recording time to ignition in software

- USB data logging module with calibration equipment

- Windows 10 control computer with 24-inch screen

Additional options:

- Video recording system

- Automatic burner ignition system

- Circulating cooler

- Anemometer for exhaust flow measurement

Technical requirements:

- Electricity: 230V AC 50Hz / 110V AC 60Hz, 10 A

- Gas supply: methane and air mixture (1 sl/min, min. 1 bar)

- Air supply: clean dry air (5 sl/min, 1 bar)

- Water supply: cooling flow 0.3–1 l/min

- Extraction ventilation: adjustable up to 500 m³/h