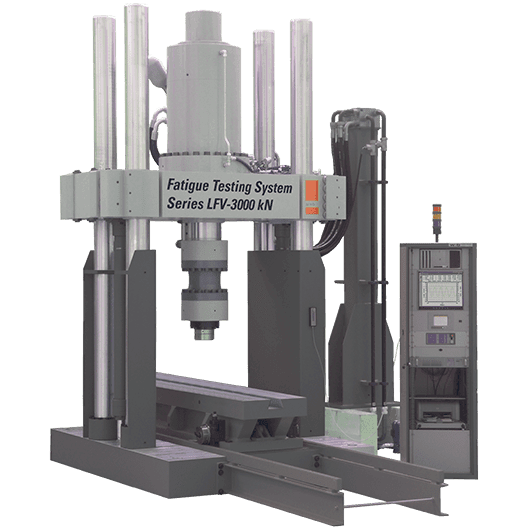

LFV Multifunctional Dynamic and Fatigue Testing Systems is an advanced technology that covers a wide range of dynamic and fatigue testing capabilities up to 630 kN. This system is designed to achieve maximum accuracy and durability when testing the resistance of materials and components to various loads. The LFV series devices are particularly useful for performing complex fatigue tests and long-term dynamic tests, ensuring both short-term and long-term resistance evaluation.

Main features of LFV systems:

- High power: The system is designed to operate at high loads of up to 630 kN, which allows testing of extremely strong materials.

- A wide range of dynamic and fatigue tests: The system is adapted to both dynamic and long-term loads, allowing testing of various components in different industries.

- Servo-control: A high-precision servo-control system ensures precise control of force, deformation and stress.

- Software: Integrated software allows you to monitor test progress in real time, collect data, perform detailed analyses, and generate reports.

- Compact design: Although the system is very powerful, its compact design allows for efficient use of space in laboratories.

- Modular design: The system can be customized according to customer needs using various accessories, such as strain gauges, load cells, and grippers.

Technical specifications:

| Specification | Value |

|---|---|

| Maximum load | Up to 630 kN |

| Test types | Dynamic, fatigue |

| Frequency range | Up to 250Hz |

| Power control accuracy | ± 0.5 % |

| Management system | Servo-hydraulic |

| Software | Real-time data monitoring and analysis |

| Available accessories | Grippers, load cells, strain sensors |

Areas of use:

- Aviation: Durability studies of materials and components under dynamic and fatigue loading regimes.

- Automotive industry: Component durability tests to assess their resistance to long-term dynamic loads.

- Materials Sciences: Used to perform accurate and long-term material resistance tests to assess mechanical properties.

The LFV series of multifunctional dynamic and fatigue testing systems ensure a high level of accuracy, making them particularly suitable for use in industrial applications where continuous assessment of the durability and strength of materials is required.