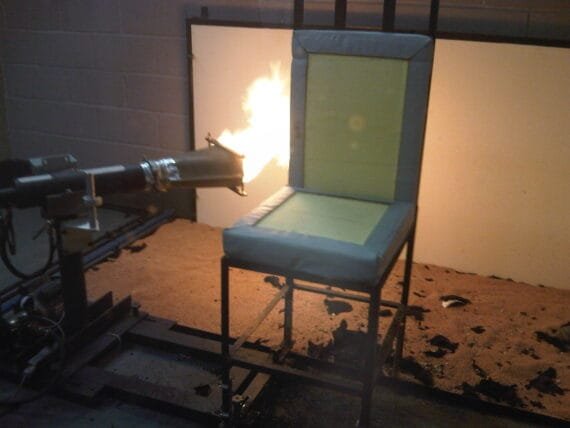

Floor covering flammability testing system corresponds EN ISO 9239-1 and EN ISO 9239-2 standards. This is the main method for testing the flammability of floor coverings according to Euroclasses system. The test determines the rate of flame spread in a floor covering under radiant heat exposure simulating a growing fire situation in an adjacent room or corridor. The results are used to classify flooring materials into A2FL, BFL, CFL and DFL classes according to BS EN 13501-1:2007 + A1:2009.

The device can also be used for tests according to ASTM E648 and DIN 4102, part 14.

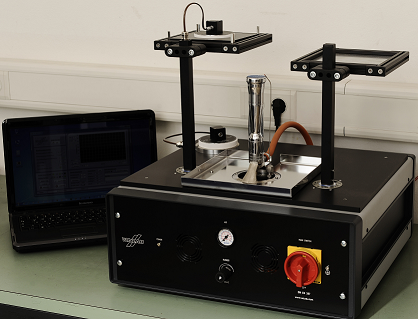

The test chamber consists of insulated supporting structures, covered with painted metal panels and insulated with calcium silicate boards. A temperature-resistant window is installed for observation. Specimen holder made of stainless steel and mounted on a sliding platform, ensuring safe and convenient sample loading.

Built-in device fiber metal mesh heating panel, whose gas and air supply is electronically regulated. The control system maintains a stable combustion mixture, guaranteeing a constant heat flow throughout the test duration.

Specification and features

- Isolated chamber, stainless steel hood with exhaust vent

- Calibration system, including calibrated heat flow meter and specimen holder

- Sliding specimen holder, ensuring safe loading

- Gas-fired heating panel with fibrous metal mesh

- Mass flow gas regulator with fine adjustment function

- Calibrated optical pyrometer for surface temperature measurement (optional)

- White light LED system for smoke density measurement

- Propane pilot burner with flame detection sensor

- Exhaust hood and air exhaust duct

- Data recording system, including:

- A computer with 24” screen

- Data acquisition equipment and cables

- Displaying test data and generating reports

- Software compatible with Windows 10

- ISO 9239-2 available as an optional upgrade

- Documentation (in English):

- Certificate of Conformity

- Calibration certificates for heat flow meter and pyrometer (if ordered)

- Complete user guide

Technical data and requirements

- Electricity: 120 V AC 60 Hz / 230 V AC 50 Hz, 10 A (excluding exhaust fan)

- Dimensions: 2400mm (W) × 2300mm (H) × 700mm (D)

- Weight: 400 kg

- Operating temperature: 10°C – 35°C

- Gas: Air and propane mixture

- Propane: 1 kg/hr, 1-2 bar, min. purity 95%

- Clean, dry air: 3-4 bar

- Water supply: 1 l/min flow with drain or recirculation system for cooling the heat flow meter

- Air removal system: Air speed 2.5 ± 0.2 m/s, maximum flow 2500 m³/h