Bettersize Instruments Ltd. BeVision M1 Automatic Static Image Analyzer

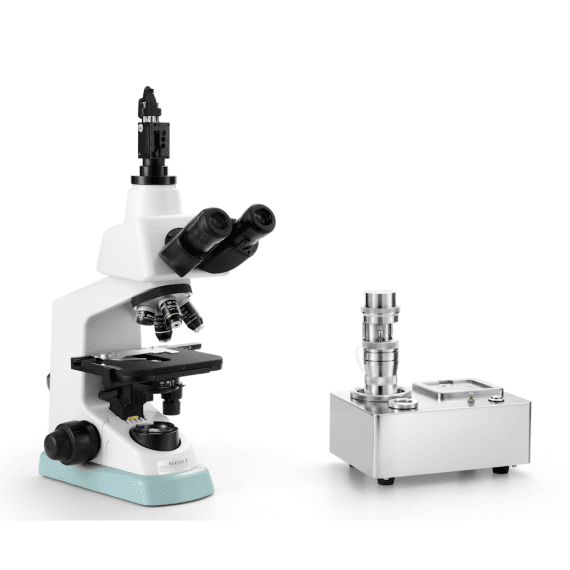

BeVision M1 is an automated image scanning system designed specifically for the analysis of filter particle cleanliness. Equipped with a metallurgical microscope, programmable motorized stage, autofocus function and high-resolution CMOS, BeVision M1 can capture and identify each individual particle, automatically merging the images into a large overall image.

- Features and benefits:

- Measuring range: 1 to 10,000 µm

- Results are in accordance with ISO 9276-6

- High reproductive measurements

- High speed CCD camera

- Powerful software makes work easier

- Automatic sample stand with high position accuracy

- 24 different particle size and shape parameters

- An important part of surface cleanliness measurements

- Why choose the image analysis method?

- Simple

Capture a photo of particles, identify them, then measure their size and shape. Every step of the image analysis is simple and straightforward. - Shape analysis

Based on direct viewing of particles, it is possible to analyze not only the size of particles, but also their shape. - Seeing is believing

The image analysis method determines the size and shape of each individual particle and then reduces them statistically. The details of the particle size or shape distribution can be accurately presented.

- Simple

- Why choose the static image analysis method?

- Clear view

In static image analysis, microscopes and high-resolution cameras are specialized for high-quality particle images. - Sensitivity to small particles

The static image analysis method is sensitive to small particles; it is even possible to estimate the size of small particles. - Small sample volume

For the static image analysis method, a small sample volume is sufficient. A few drops of emulsion or a few micrograms of powder are sufficient for the measurement.

- Clear view

- Efficient scanning and panoramic mode

- Scan Mode

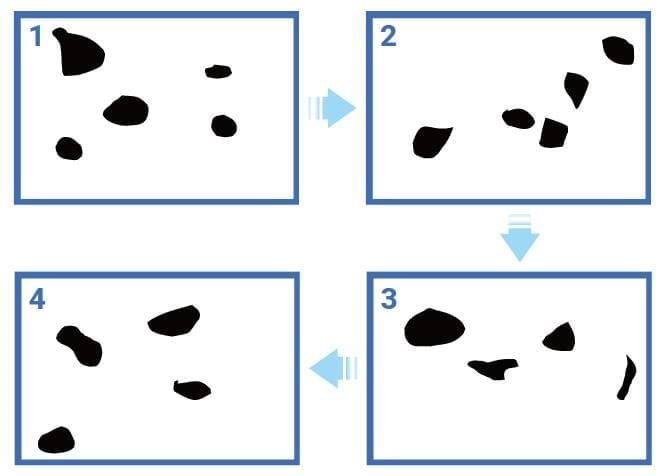

The BeVision M1's scanning mode workflow is to first capture a photo, then analyze the image as the stand moves, capture another photo when the stand reaches a new position, and repeat.

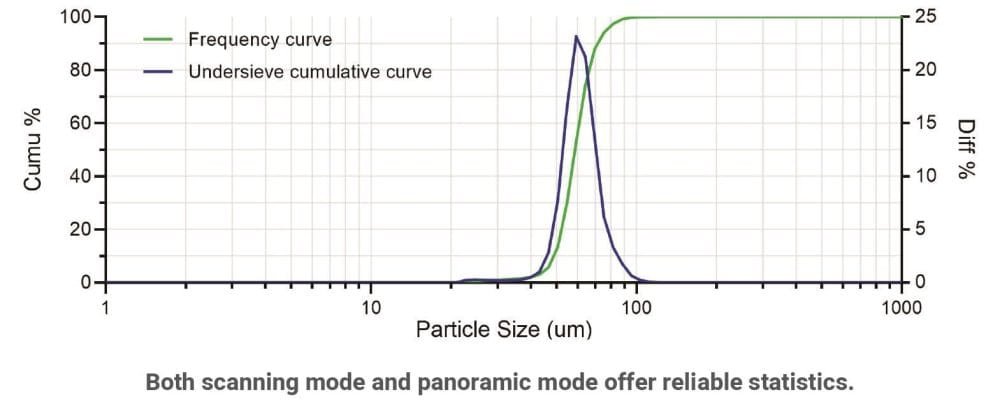

BeVision software displays results live during the scanning process. The scanning mode is widely used due to its efficiency and reliability.

- Efficient and reliable scanning mode

The automatic scanning process improves testing efficiency by simultaneously capturing images and moving the stand, increasing efficiency to the next level. The efficient scanning mode analyzes many particles in a single test, thus enhancing the statistical significance of the result.

- Efficient and reliable scanning mode

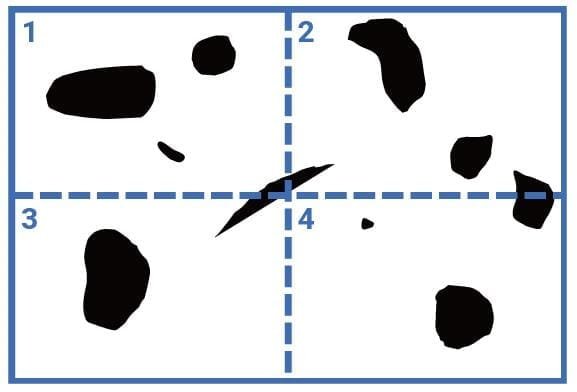

- Panoramic Mode

Panorama mode is the stitching of individual images into a panorama before analysis. With a panorama, it is easy to measure the number of all particles in a region and the size and shape of each particle, even if the particle is large. Accurate particle counting is very important for different industries, such as the automotive or pharmaceutical industries.- Combining macrovision with microdetails

BeVision M1 is designed with a panorama that records all particles that are emitted in the millimeter-level region and preserves their shape details. The clear panorama helps to accurately count particles in the macro region and analyze particle size and shape without any residue.

- Combining macrovision with microdetails

- Scan Mode

- Particle Size and Shape Parameters:

- Size parameters:

Equivalent diameters: area equivalent diameter, perimeter equivalent diameter;

Ferret diameters: maximum and minimum Ferret diameter, XLF (“length”);

Martin diameters: maximum and minimum Martin diameters;

Legendre ellipse: major and minor axes;

- Form parameters:

The size of the difference in 2 directions: aspect ratio, L/W ratio, ellipticity ratio;

For roundness and upright shape: roundness, irregularity, density, expansion ratio, box ratio;

Contour crack: crack, bulge, density;

For longitudinal particles: elongation, straightness;

- Size parameters:

- BeVision Software: Visualize for Insights:

Analyzers – Bettersize

More information: on the manufacturer's website or send us an inquiry!