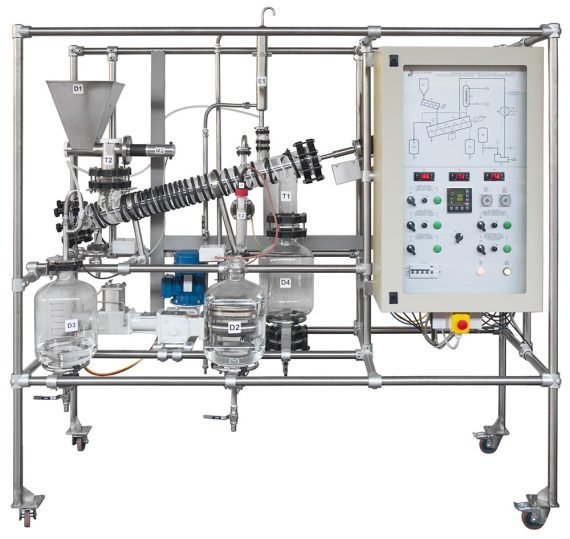

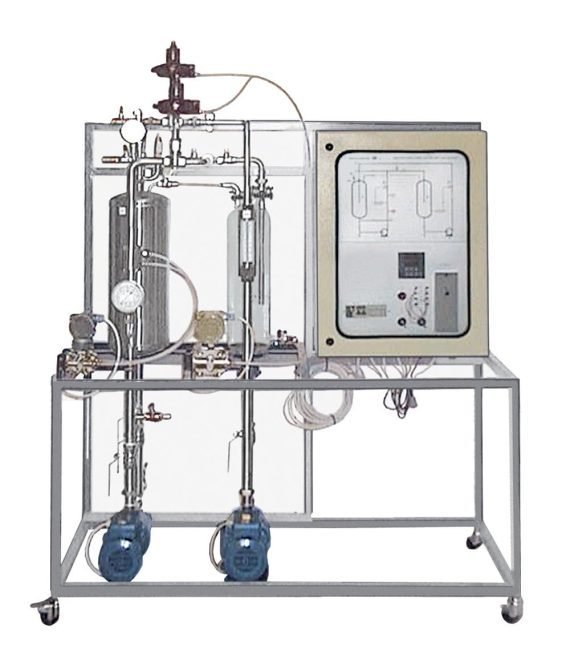

Temperature and flow control system Mod. REGA-T/EV is a high-quality training equipment designed to analyze temperature and flow control processes in industrial cycles. The system uses dual control circuits to monitor and control temperature and flow. This equipment is integrated with SCADA software, which allows real-time monitoring of processes and their control via a computer.

Technical characteristics:

- Construction:

- AISI 304 stainless steel frame with wheels;

- Tank made of AISI 304 stainless steel (40 l);

- Jacketed reactor made of AISI 304 stainless steel with agitator (capacity – 25 l);

- Three-pass tubular heat exchanger (AISI 304, heat exchange area – 0.6 m²);

- Pump:

- Centrifugal pump (stainless steel housing and rotor, Qmax – 4000 l/h, Hmax – 30 m);

- Valves:

- 1 pneumatic valve for water flow control (AISI 316, Cv = 1.25);

- 1 pneumatic valve for steam flow control (AISI 316, Cv = 0.32);

- Measuring equipment:

- Electronic variable range flow indicator (AISI 316, range 25–250 l/h);

- Calibrated diaphragm for steam flow measurement (AISI 304);

- Differential pressure transmitter (AISI 316, 4-20 mA output);

- Pt100 thermocouple sensor (AISI 316 protection);

- Thermometer (range 0–120 °C);

- Control equipment:

- Electronic PID controller with four-line LCD display and serial communication card;

- 2 electropneumatic transducers (4-20 mA / 0.2-1 bar);

- Additional equipment:

- SCADA software: real-time control and monitoring and historical data viewing;

- IP55 class control panel with synoptic diagram, fuses and emergency button.

Technical data:

- Power supply: 230 Vac, 50 Hz, single-phase, 1.5 kVA (other voltages and frequencies available upon request);

- Dimensions: 1700 × 800 × 1900 mm;

- Weight: 310 kg.

Educational program:

- Analysis of PID control methods;

- Operating principles of temperature and flow measuring devices;

- Temperature cascade control;

- Research on process characteristics and response time;

- Controller tuning techniques;

- System monitoring via SCADA program.