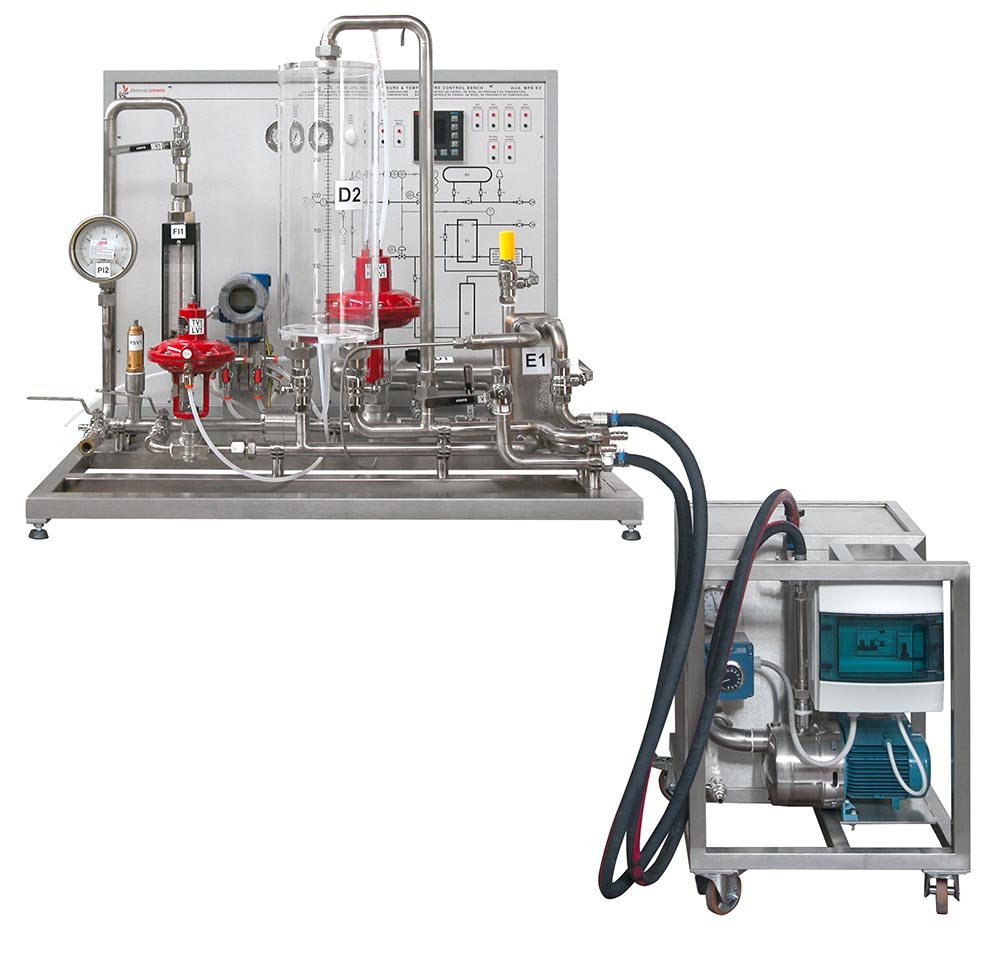

Multi-process control stand Mod. MPB/EV is a compact training device for controlling and analyzing flow (air and water), level, pressure and temperature processes based on a single controller. Manual valves allow changing the hydraulic scheme, and SCADA software allows controlling and monitoring the system on a computer.

Technical characteristics:

- Construction: AISI 304 stainless steel frame;

- Measuring instruments:

- Variable area flow meter (0–1000 l/h);

- Differential pressure sensor (0–500 mm H₂O);

- Pressure sensor (0–6 bar);

- Pressure gauge (for I/P converter output signal);

- Capacity: 5 liter graduated Plexiglas container;

- Heat exchanger: Stainless steel plate heat exchanger;

- Control valves:

- Pneumatic valve (Cv = 0.25, AISI 316);

- Pneumatic valve (Cv = 0.13, AISI 316);

- Other components:

- Electropneumatic transducers (4–20 mA / 0.2–1 bar);

- Safety valve;

- Water heating generator with AISI 304 stainless steel tank, electric heating element, recirculation pump and thermostat;

- Pipelines and valves made of AISI 304 and 316 stainless steel;

- Junction box made of painted carbon steel with synoptic view, fuse (ELCB) and measuring terminals for controller signals.

SCADA software:

- Allows monitoring and control of ON-OFF and analog signals from a PID controller;

- Visualization and analysis of real-time and historical data.

Technical data:

- Power supply: 230 Vac, 50 Hz, single-phase, 0.5 kVA (other voltages and frequencies available upon request);

- Dimensions: 850 × 800 × 750 mm;

- Weight: 50 kg.

Additional options:

- Service block mod. US-1/EV – for closed-loop operation (without temperature control).

Educational program:

- Analysis of PID control methods;

- Flow, level, pressure and temperature control;

- Controller tuning techniques;

- Evaluation of system responses to disturbances.