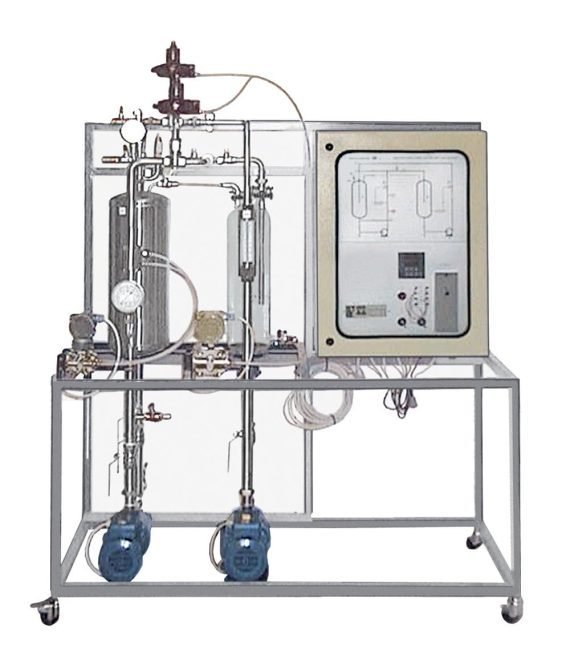

Solid-liquid extraction pilot plant SOLID-LIQUID EXTRACTION PILOT PLANT is designed for continuous countercurrent extraction for use in chemical engineering experiments. The device uses an Archimedean screw to ensure continuous movement of the solids, while the solvent moves countercurrently under the influence of gravity.

The solid phase is fed through an AISI 304 stainless steel funnel, and the solvent is fed into the extractor from above by a peristaltic pump. Automated model SLa/EV also has a PID controller, which allows automatic adjustment of the solvent preheating temperature, ensuring more precise process control.

Curriculum:

This experimental station allows you to deepen your knowledge about:

- Theoretical stage calculations;

- Analysis of extraction efficiency by varying the flow, nature and temperature of solids and solvent;

- Extraction of different materials:

- Soybean oil with hexane,

- Chlorophyll from spinach with ethanol,

- Olive pomace oil with hexane,

- Potato starch with water.

- Automatic temperature control (only SLa/EV model);

- Monitoring of the plant system via computer (only SLa/EV model).

Technical specifications (Mod. SL/EV):

- AISI 304 stainless steel frame with wheels;

- Borosilicate glass extractor (DN 100, length 1000 mm) with PTFE Archimedes screw;

- AISI 304 stainless steel funnel (2 l capacity);

- High-speed engines:

- For solid material feeding (0–20 rpm),

- For extractor Archimedes screw (0–10 rpm);

- 2 programmable timers;

- Borosilicate glass containers for solvent, extracted phase and spent solid residue (10 l each);

- AISI 304 stainless steel condenser with 0.1 m² heat exchange surface;

- 3 Pt100 thermocouples with AISI 316 sheath;

- Electronic temperature indications;

- Quartz electric heater (0.3 kW);

- Dosing pump (AISI 316) with adjustable flow 0–12 l/h;

- AISI 304 and AISI 316 stainless steel pipelines and valves;

- IP55 panel with emergency button and ELCB protection.

Automated version (Mod. SLa/EV):

- PID controller for solvent temperature control;

- System maintenance and management by computer.