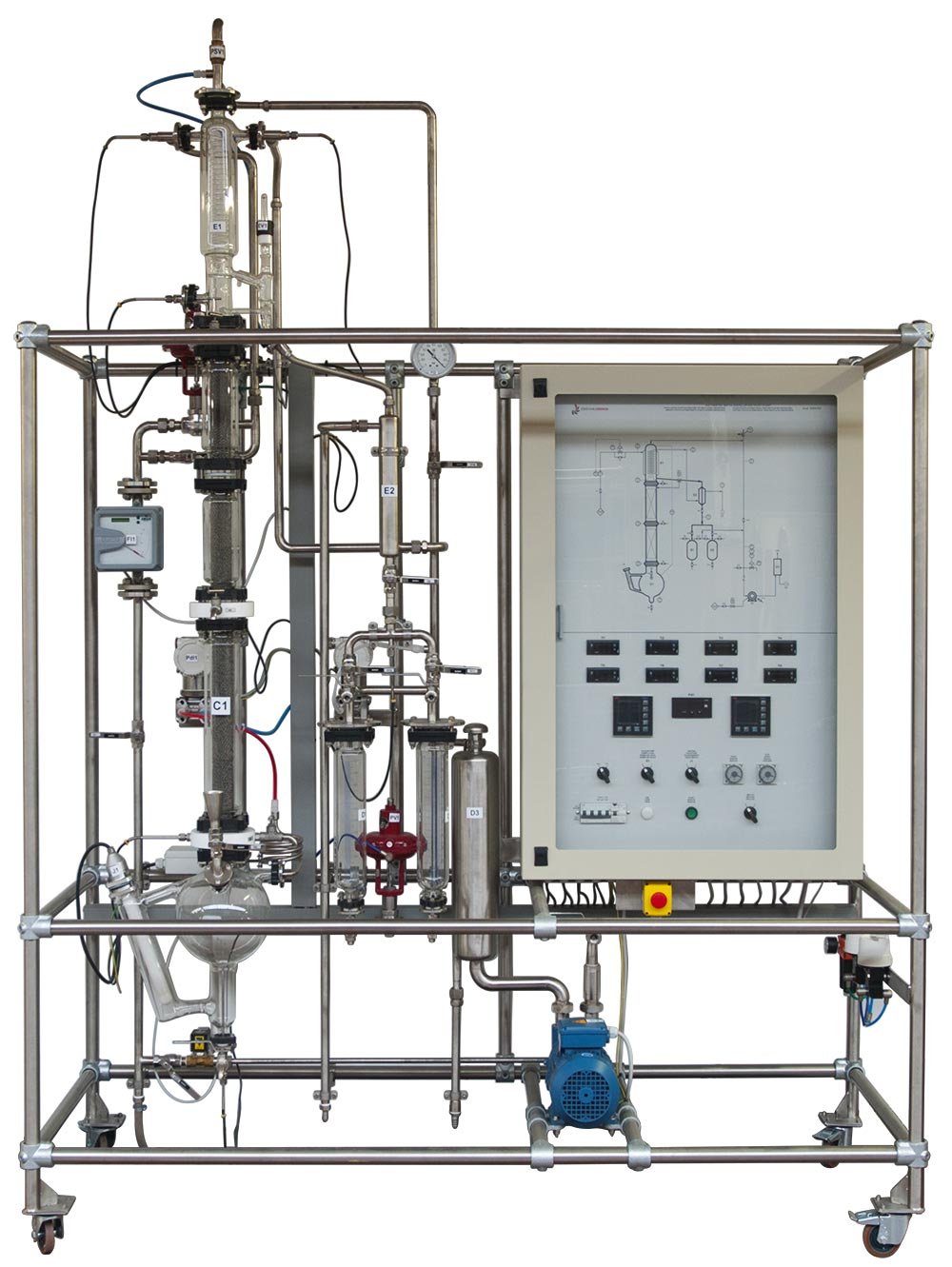

Batch distillation pilot plant DIS/EV designed to teach distillation principles and practical work with distillation systems. The device consists of a borosilicate glass distillation column with AISI 316 stainless steel mesh packing, a reboiler, a condenser and a reflux head. The distillate is collected in glass containers after cooling in a tubular heat exchanger.

The automated version (DISa/EV) has PID controllers that allow automatic adjustment of feed preheating temperature, condenser cooling water flow and vacuum level.

Training opportunities:

- Distillation of different mixtures (water/ethanol, water/methanol, methanol/propanol, etc.) by changing the following parameters:

- return current ratio,

- reboiler heating power,

- feed composition,

- pressure level.

- Preparation of mass and energy balances.

- Calculation of the theoretical number of pallets.

- Observation of tidal phenomena and hydrodynamics.

- Automatic flow, pressure and temperature control (DISa/EV only).

- Device monitoring via computer (DISa/EV only).

Technical specifications (DIS/EV):

- Frame: AISI 304 stainless steel with wheels.

- Column: borosilicate glass, DN 50, height – 1100 mm, filling – AISI 316 stainless steel mesh.

- Reboiler: borosilicate glass, capacity – 5 l, with quartz heater (2.5 kW).

- Capacitor: borosilicate glass, heat exchange area – 0.4 m².

- Vacuum gauge: range from -1 to 0 bar.

- Temperature gauges: 8 Pt100 thermocouples with stainless steel protection.

- Differential pressure gauge: range 0–200 mm H2O, 4-20 mA signal.

- Condensate cooling: stainless steel tube heat exchanger.

- Vacuum pump: circular, power – 0.7 kW.

- Flow meter: range 0–250 l/h.

- Dimensions: 1800 × 800 × 3000 mm.

- Weight: 300 kg.

The DISc/EV and DISa/EV models have additional data logging and automatic control equipment, including:

- Absolute pressure gauges (range 0–1000 mbar).

- PID controllers with multidirectional control loops (DISa/EV).

- Computer monitoring and data logging software.