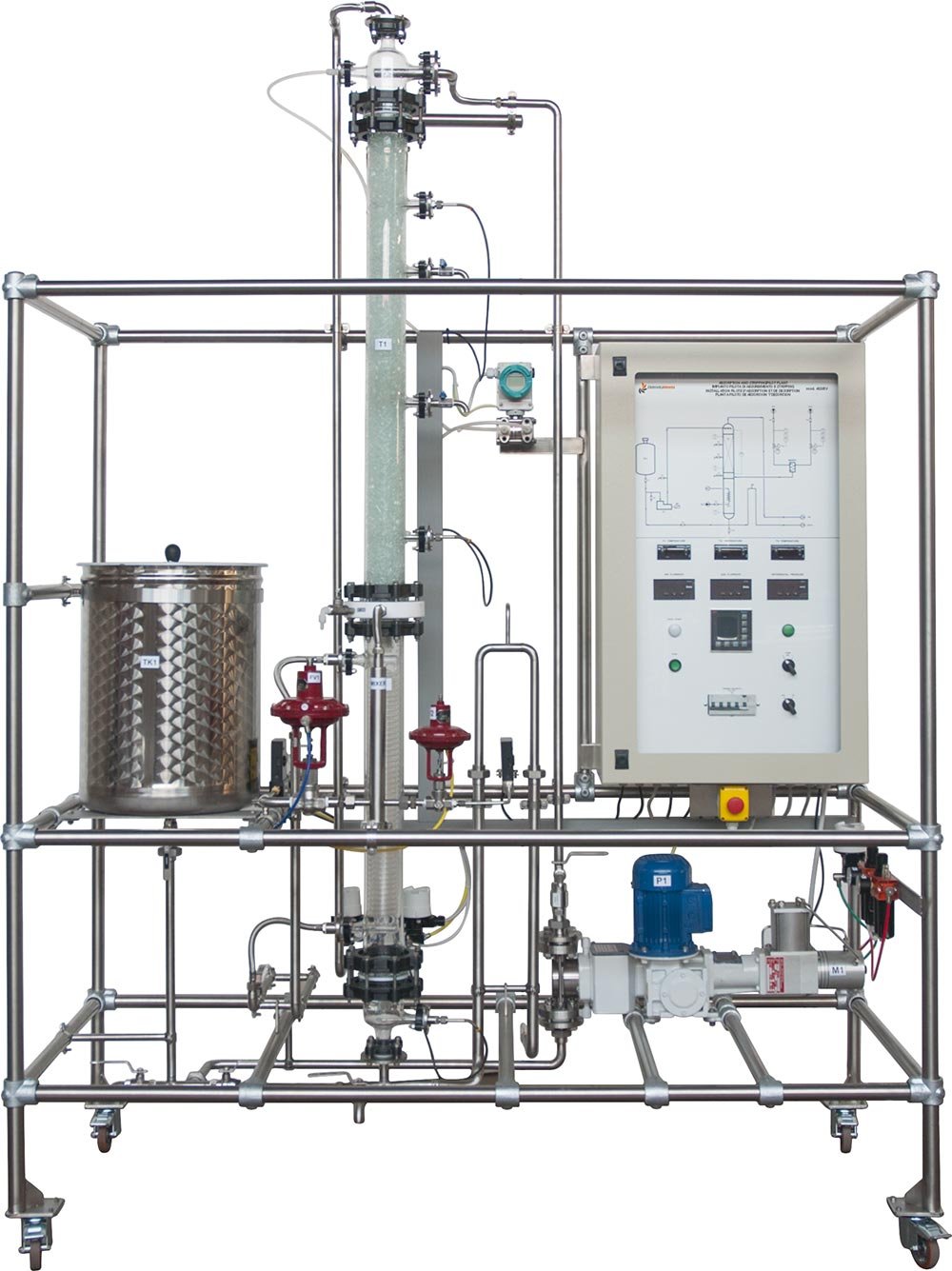

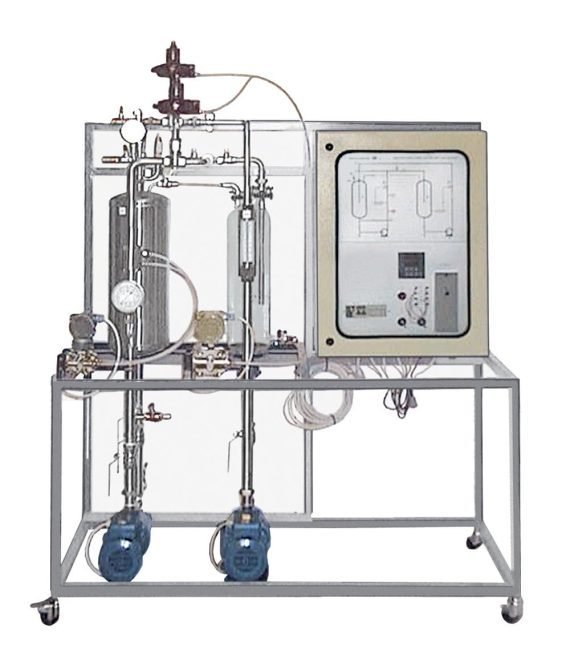

Absorption and stripping pilot plant ADS/EV is intended for chemical engineering training and allows the study of mass transfer between the gas and liquid phases. This stand can be used for absorption processes (addition of a gaseous substance to the liquid phase) and stripping processes (separation of the liquid phase to the gas phase). The ADSa/EV automatic version is supplemented with a PID controller, which allows automatic regulation of gas flows.

Main features:

- Construction: Made of AISI 304 stainless steel with wheels for mobility.

- Column: borosilicate glass DN 80, height – 1000 mm, filled with Raschig rings.

- Heat exchanger: borosilicate glass, 0.5 m² heat exchange surface, installed at the bottom of the column.

- Power tank: 30 l capacity, made of AISI 304 stainless steel.

- Dosing pump: AISI 316 stainless steel, with pneumatic control (Qmax = 270 l/h).

- Pneumatic control valves: AISI 316 stainless steel, DN 15, Cv = 0.2 and 0.08.

- Electronic mass flow meters: AISI 316 stainless steel, with different ranges (0–600 Nl/h and 0–6000 Nl/h).

- Differential pressure transmitter: range 0–200 mm H2O, with 4–20 mA signal.

- Temperature sensors: three Pt 100 thermistors with reading indicators.

- Control panel: IP55 class, compliant with EU standards, with emergency button.

Training opportunities:

- Analysis of absorption efficiency under different conditions.

- Monitoring the stripping process using various gases.

- Calculation of theoretical stages.

- Automatic flow control with PID controller (only mod. ADSa/EV).

- System monitoring via computer (only mod. ADSa/EV).

- NH3 absorption using H2O and CO2 absorption with NaOH solution.

Technical data:

Dimensions: 1900 × 800 × 3000 mm

Weight: 270 kg