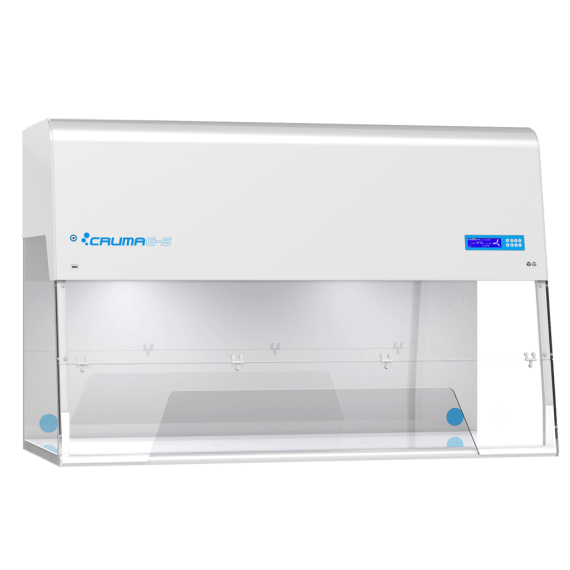

BioAir SpA Safemate Cyto series cytotoxic drug safety cabinet

- For the preparation of chemotherapeutic antitumor drugs

- Manufactured according to DIN12980 and EN12469:2000 standards

- Modern microprocessor control system

- Large digital display, high resolution

- Air and particle-tight sliding glass door, electrically operated with a finger touch

- Low airflow and incorrect front window position alarms

- Lowered front and rear walls for easy access

- Front access to tertiary filter for maintenance and service

- Bag-in bag-out tertiary filter replacement technology (according to KTA 3601)

- Easy upgrade options

Key specifications

These latest generation cytotoxic drug handling cabinets are certified to the strictest safety cabinet standards in this category (DIN12980, EN12469). The internal design, airflow aerodynamics and monitoring, built-in safety features and a highly precise manufacturing process guarantee the highest performance in accordance with DIN 12980 and EN12469 standards.

In addition to two classic H14 filters for the extracted air and the unidirectional recirculated air flow, a tertiary filtration stage (with a bag-in bag-out filter changing protocol according to KTA 3601) is installed under the work surface to ensure the necessary safety for maintenance personnel when changing this filtration stage.

Four security levels:

- Operator safety (very high opening safety factor), identical to that provided by a Biological Safety Cabinet

- Environmentally friendly (double H14 filtration stage for suction)

- Safety for the product and between products (class 100 in the work area)

- Safety for engineers when changing the tertiary filtration stage (bag-in bag-out procedure)

Technical specifications

- Microprocessor controlled motor fan with exhaust air flow monitoring sensor

- Modern microprocessor control system with:

- On a big screen

- Automatic control of set air flow rates

- Sliding glass door with smart control

- Full-time monitoring of HEPA filter life

- Signals. Multiple signals with backup functions.

- Continuous display of working conditions

- Highest air flow stability both during transient disturbances and during progressive filter clogging

- Semi-automatic fumigation cycle

- Ensuring the highest operator safety by constantly monitoring the airflow of the front barrier

- Low barrier signal

- Power failure signal

- Boltless contact for remote monitoring of the exhaust fan

- Automatic recovery of preset conditions in case of power failure

- Ready to install a 19-inch LCD monitor on the back (monitor not included)

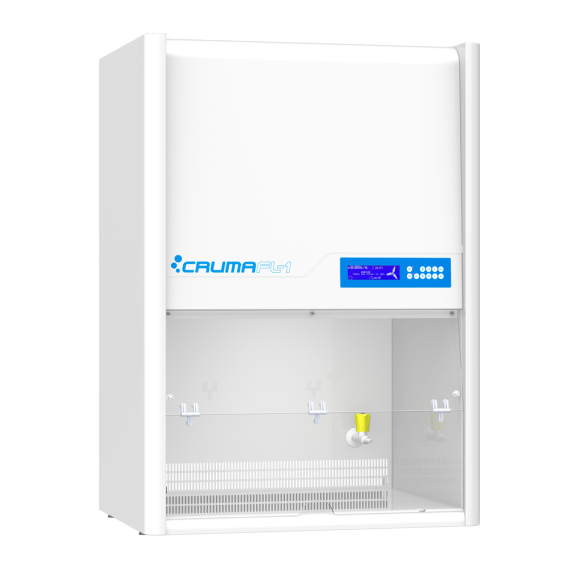

- Sliding front design for comfortable work. Lowered rear wall of the working chamber for best distribution of the continental flow

- Tools installed from above

- Stainless Steel internal surfaces with SB finish (including spill tray). Solid or perforated work surface (30 cm sectors) and specially designed front grille for unrestricted air circulation

- Electrically operated sliding laminated safety glass door (maximum opening up to 120°)

- Convenient 200 mm front opening

- Easy installation options through the sides

- Open exhaust HEPA filter for easy visual inspection of integrity.

- Three H14 efficiency class particle filters with 99.999% efficiency for 0.3 micron particles (maximum penetrating particle diameter) (EN1822-1)

- Filter change and maintenance from the front

- "Bag-in bag-out" tertiary filter replacement technology (avoiding interruption of insulation continuity in the work area when replacing the filter according to KTA 3601)

- Suction transitions are easy to install

- Key operated. The key can be removed when the unit is in the LOCK mode to prevent unwanted operation. In the event of a power failure, the cabinet is returned to its original state conditions.

- Automatic calibration cycle when the cabinet is turned on.

- A quick rinse and setup cycle is performed before reaching the SAFE operating mode.

- Visual indication of SAFE conditions. Warning before reaching actual signal conditions (visual and audible signals)

- Soft key control for standard services. UV and fluorescent lights linked together.

- Extraction and recirculation flow rates provide 25 air changes per minute in the work area (30%/70% split)

- Front barrier air velocity ≥ 0.5 m/s

- Opening protection factor (Apf) ≥ 1.5 x 105

- Maximum power (for each power point) 3 Amps.

- The microprocessor is equipped with an analog security dog

- CE certification according to Machinery Directive 89/392/EEC, 91/368/EEC, 93/44/EEC 93/68/EEC. Shipped in two parts (two pallets)

ADDITIONAL FEATURES

- Active windscreen belt tension control system. This mechanism stops the windscreen suspension straps from being pulled out if a collision occurs or an obstacle is detected in the window movement. This ensures that the glass does not fall unexpectedly and reduces the risk of injury during window movement.

- ECO mode: This operating mode allows you to reduce energy consumption and noise levels while maintaining a sterile interior work area. When activated, the front glass door will be lowered a few centimeters from the work surface and the motor fan will slow down. The reduced opening will allow less air flow to keep the front barrier active. Operation is not allowed in ECO mode.

CONTROL PANEL

The controls are located on the front of the cabinet and include a control key and an LCD display. The microprocessor will regulate the fan to maintain the air flow at set values based on the feedback from a sensor installed in the exhaust path. Access control is provided by a key for user on/off and a numeric password for access to the calibration and service menus.

- The following parameters are monitored:

- Laminar vertical flow velocity;

- Front barrier flow velocity;

- Audible/visual signals for insufficient airflow, fan failure, front window position;

- Remaining time of UV radiation;

- Controls for counting hours: cabinet, HEPA filters, UV lamp.

- The following control elements are controlled:

- Cabinet ON/OFF button;

- White light ON/OFF;

- Internal plugs ON/OFF;

- Open/close the combustion gas solenoid safety valves;

- UV light timer;

- Activating ECO mode.

- The electronic board provides a voltage-free switch to turn off/on the external fan or alarm.

for remote work.

Cytotoxic Drug Safety Cabinets – BioAir laboratory furniture group

More information: on the manufacturer's website or send us an inquiry!