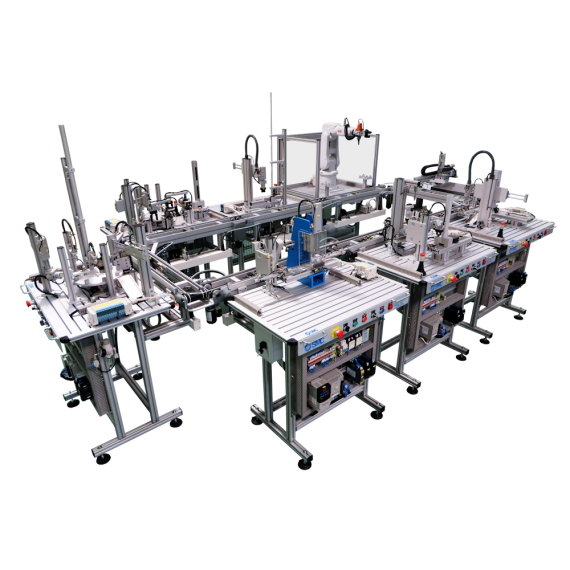

SMC España SAU FAS-200 Flexible Assembly Simulator

- FAS-200 – Flexible and compact mounting system

- FAS-200 consists of up to 18 independent stations with integrated control.

- Modular equipment accommodates more stations in the same space, allowing more users to work simultaneously.

- Allows for phased investment, starting with an initial configuration that is easy to expand by adding workstations.

- Provides professional training in industrial automation skills using standardized industrial parts.

- Each station in the FAS-200 system performs a part of the process.

- Includes the TROUB-200 fault simulation system, which generates up to 16 different faults that are diagnosed by the user.

- FAS-201: Base supply/inspection station

- Provides a base that serves as a support mechanism and verifies its correct orientation/position.

- FAS-202: Base rejection/transfer station

- The second station places correctly placed bases on pallets and rejects incorrect ones.

- FAS-203: Bearing supply/transfer station

- Feeds the bearing and moves it to the measuring position. Various bearings with different heights are available.

- FAS-204: Bearing measuring/transfer station

- Measures the height of the bearing supplied by the previous station and places it in the base.

- FAS-205: Hydraulic stop

- Emulates bearing pressure into the base.

- FAS-206: Transfer station to hydraulic station

- Feeds the workpiece to the press station and places/moves it onto pallets.

- FAS-207: Shaft classification station

- Feeds the mounting shafts and checks their material and position. There are two types of shafts with different materials.

- FAS-208: Shaft rejection/transfer stop

- Rejects misaligned or poorly positioned shafts and places the correct ones in the work piece.

- FAS-209: Lid classification station

- Feeds and inspects covers to be placed on the workpiece. There are 6 different types of covers with various materials, colors and heights.

- FAS-210: Lid rejection/transfer station

- The tenth station rejects unsuitable covers or places them on the work piece if they fit.

- FAS-211: Screw supply station

- Feeds and moves screws to be inserted into the workpiece to the next station.

- FAS-212: Screw insertion station

- Inserts four screws into the base of the workpiece. Given that the screw feed occurs in only one place, the reusable mechanism performs the following pallet rotation movements.

- FAS-213: Robotic screw stop

- Integrates robotics technology widely used in automated environments. In this part of the process, an industrial robot picks up four screws inserted into the product at the previous station.

- *Check available robot options.

- FAS-214: Transfer and visual inspection station

- Performs quality control of the work piece using an artificial vision system. In the inspection position, the artificial vision system examines the assembled components.

- FAS-215: Rejection stop after visual inspection

- Rejects a work detail if the inspection result is unsatisfactory.

- FAS-216: Storage station

- The product is removed from the production line and stored using electric actuators.

- FAS-220: Pallet transfer station

- This station moves a pallet with a workpiece from one transfer line to another using a parallel transfer configuration.

- FAS-230: Linear transmission for 4 stops

- The FAS-230 moves the pallet between stations. Each transfer connects 4 stations.

Assembly – Simulators – SMC

More information: on the manufacturer's website or send us an inquiry!